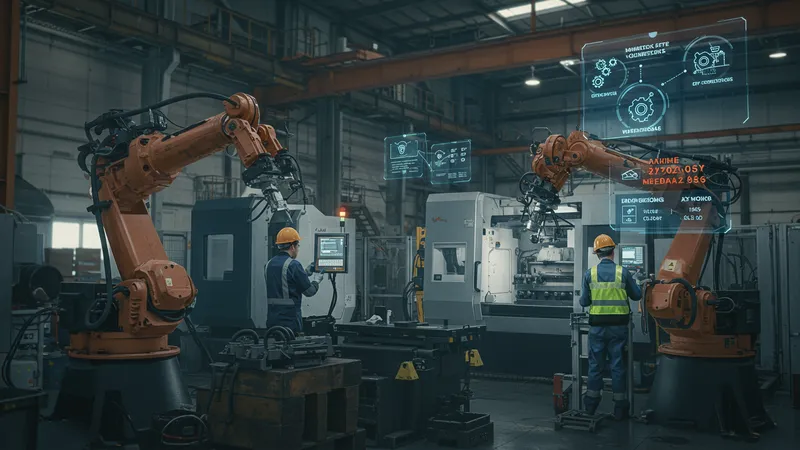

Explore The Power Behind Top Industrial Machines

The True Cost of Maintenance and Operation

Operating these industrial beasts isn’t just about switching them on and letting them run. The true financial burden lies in maintenance costs, unexpected downtimes, and the skilled labor required to keep them functioning. Often overshadowed by purchase price, these ongoing expenses can exceed initial investments over time.

Take industrial robots, for example. Their need for constant calibration and software updates can quickly inflate costs. But there’s one more twist—some companies are shifting to pay-per-use models, fundamentally altering the economic landscape and offering new opportunities for small businesses entering the market.

Unexpected equipment malfunctions impact productivity and lead to significant financial losses. Factory managers now focus on predictive maintenance using IoT solutions that anticipate issues before they occur. But what you read next might change how you see this forever.

As you consider the hefty investments in upkeep, think about the trade-off between cutting-edge technology and financial strain. Which secrets are companies still hiding to keep you investing in these indispensable machines? Find out more on the next page…